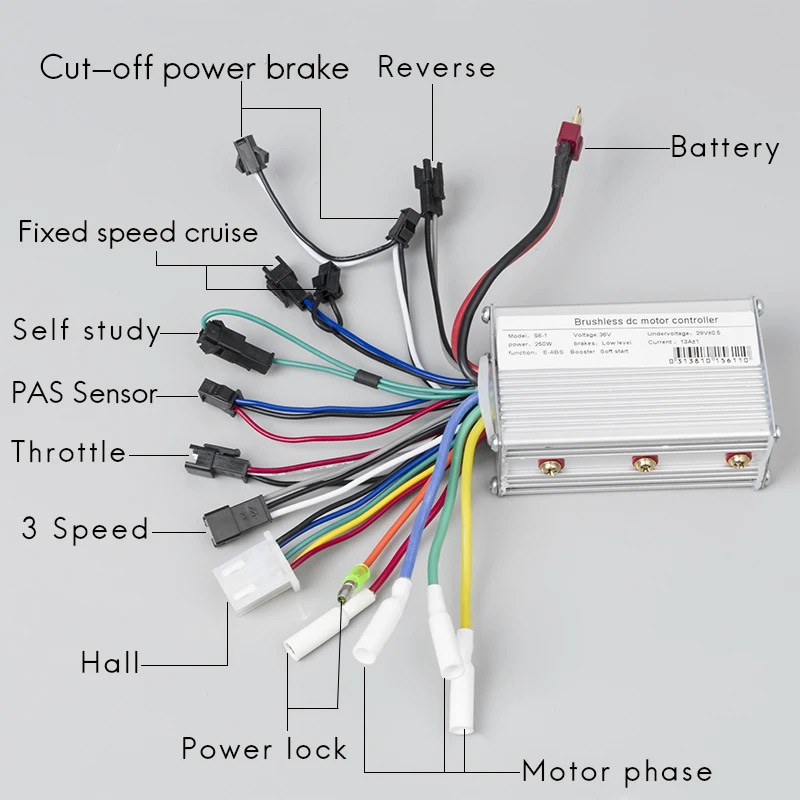

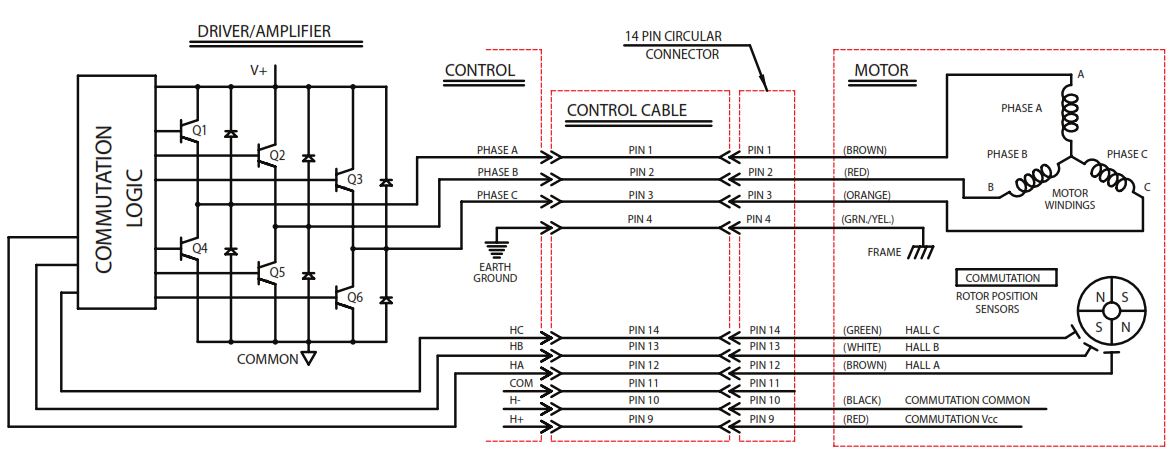

One common setup is called the full bridge drive circuit. Ebike brushless motor controller identification of wires.

Brushless Motors Bldc Motor Sensorless Motor Motor

Brushless dc motor wiring diagram. Brushless dc motors were made possible by the development of solid state electronics in the 1960s. With the advent of cheap computers and power transistors it became possible to turn the motor inside out and eliminate the brushesin a brushless dc motor bldc you put the permanent magnets on the rotor and you move the electromagnets to the stator. Unfortunately this one hasnt come with any wiring diagram. Motor control part 1. An electric motor develops torque by alternating the polarity of rotating magnets attached to the rotor the rotating part of the machine and stationary magnets on the stator which surrounds the rotor. By plug i mean the diagram that describes what each of the wires coming out.

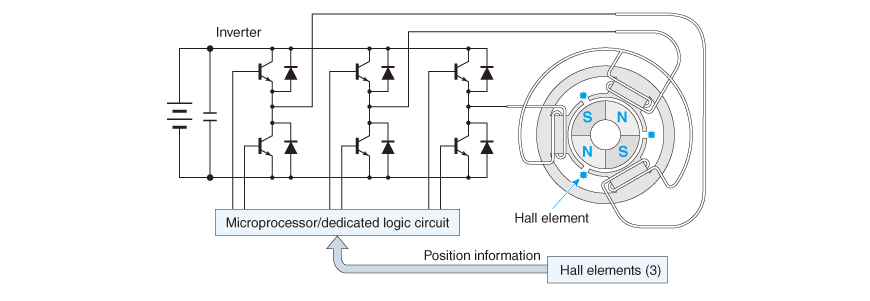

The brushless dc bldc motors increasing popularity is due to the use of electronic commutation. Bldc motors are superior to brushed dc motors in many ways such as ability to operate at high speeds high efficiency and better heat dissipation. Then you use a computer connected to high power transistors to charge up the electromagnets as the shaft turns. How to find wire functions of bldc controller which dont have labels on wires. The 48v w brushless dc tricycle motor main specification. Figure 1 is a simplified illustration of bldc motor con struction.

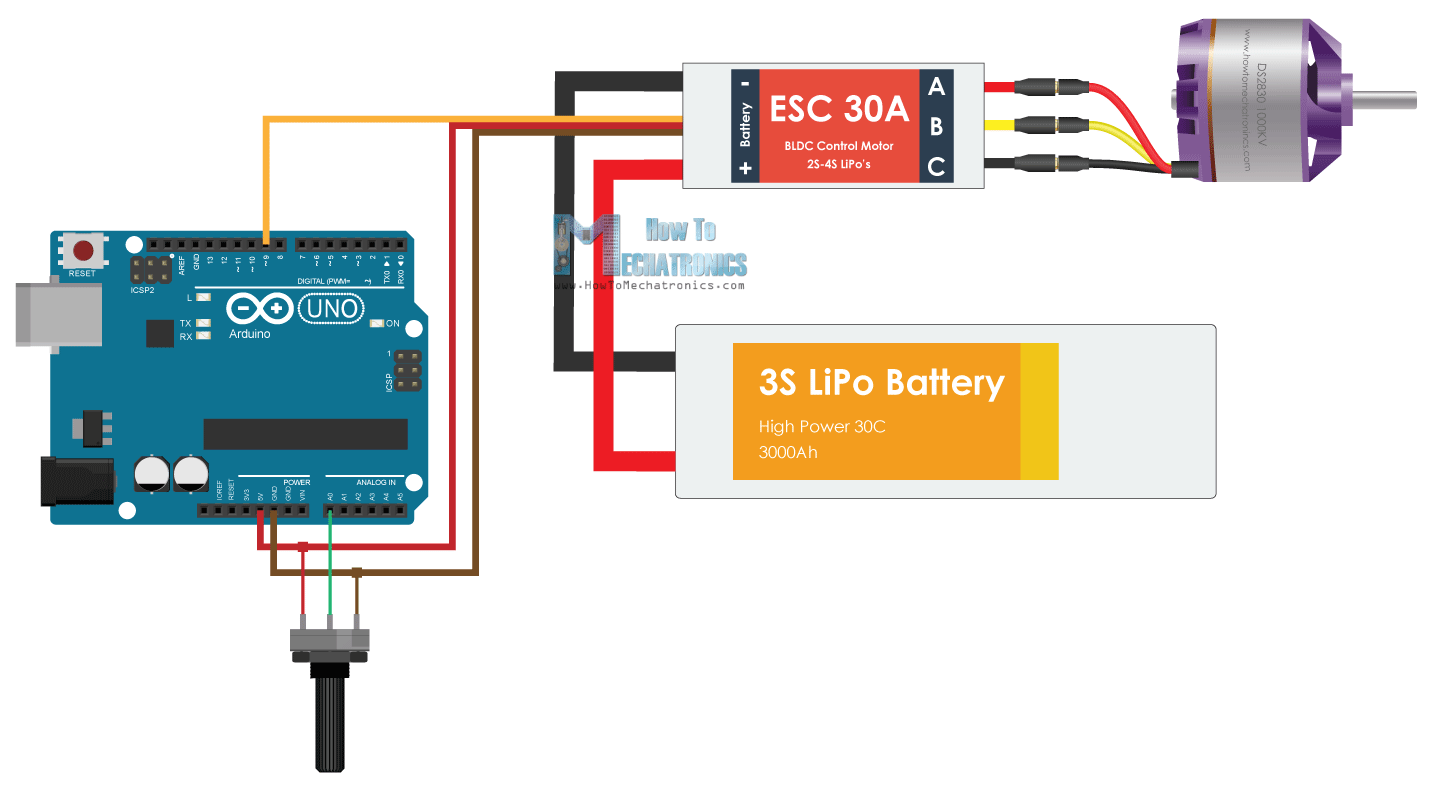

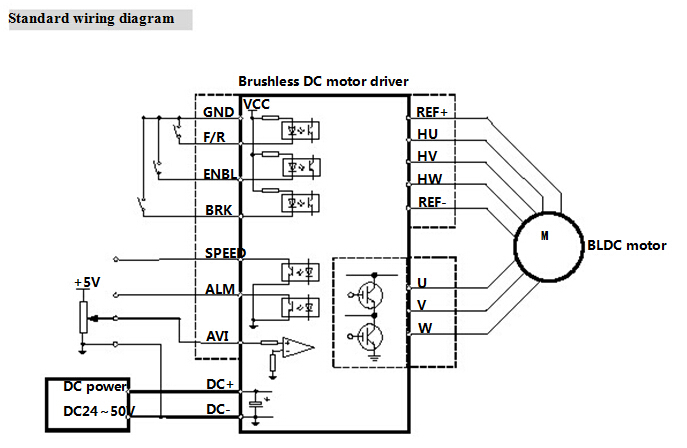

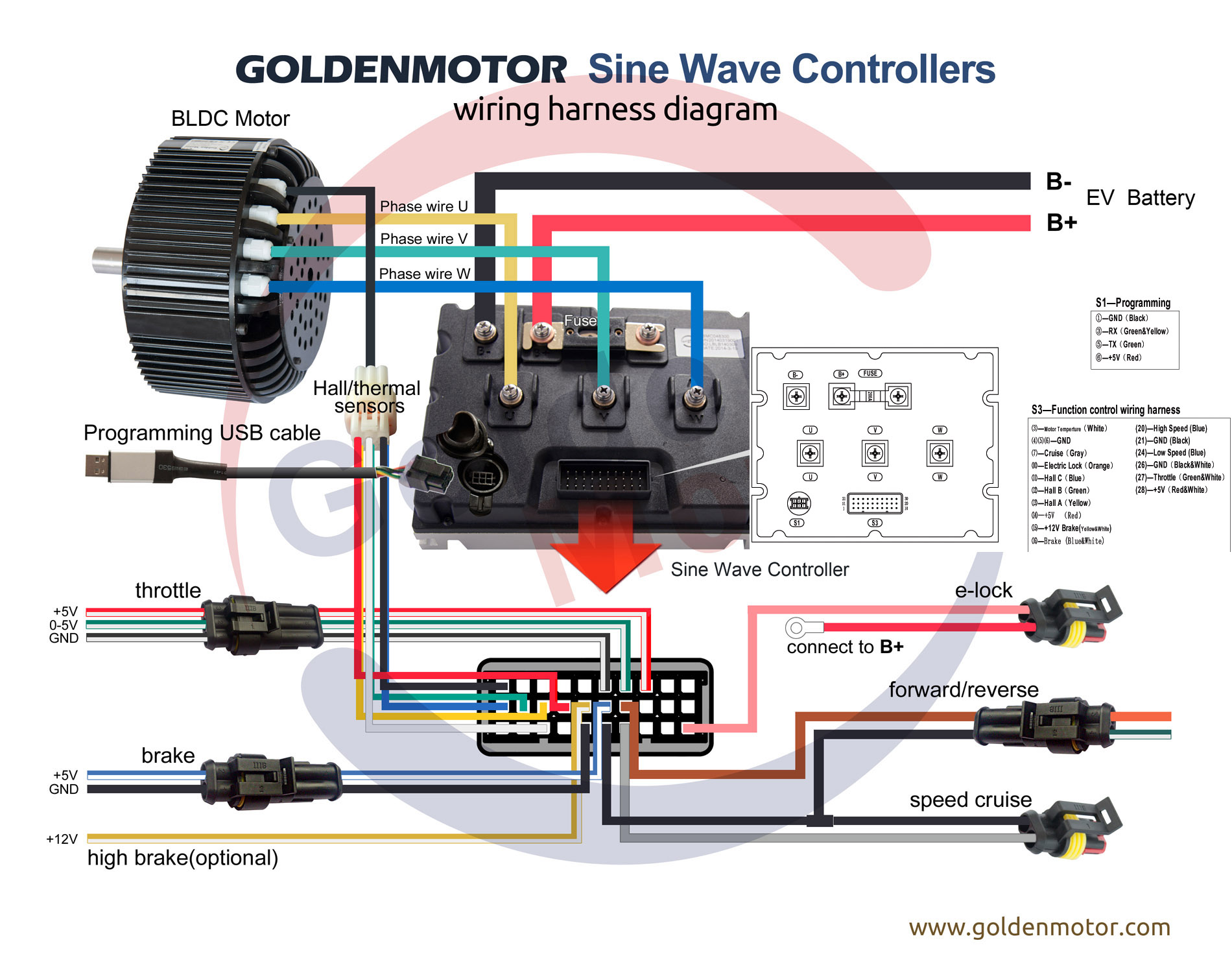

Block diagram of a typical brushless dc motor control or drive system is shown in the following image. Brushed dc motors were invented in the 19th century and are common. This drive circuitry is often known as electronic speed controller system or simply an esc. Brushless dc controllers mdc wiring diagram data schema from brushless motor wiring diagram sourceinboxmeco rc motor and esc wiring schematics wiring diagrams from brushless motor wiring diagram sourceseniorlivinguniversityco. Brushless dc motors bldc have been a much focused area for numerous motor manufacturers as these motors are increasingly the preferred choice in many applications especially in the field of motor control technology. A brushless motor is constructed with a per manent magnet rotor and wire wound stator poles.

An introduction to brushless dc motors duration. This replaces the conventional mechanics comprised of brushes rubbing on the commutator to energize the windings in the armature of a dc motor. Electrical energy is converted to mechanical energy by the magnetic attractive forces between the permanent magnet rotor and a rotating magnetic field induced in the wound stator poles.

.png)