Safety switches can be used in a variety of areas. To troubleshoot kubota safety switch issues it is often necessary to check both the switches and the wiring.

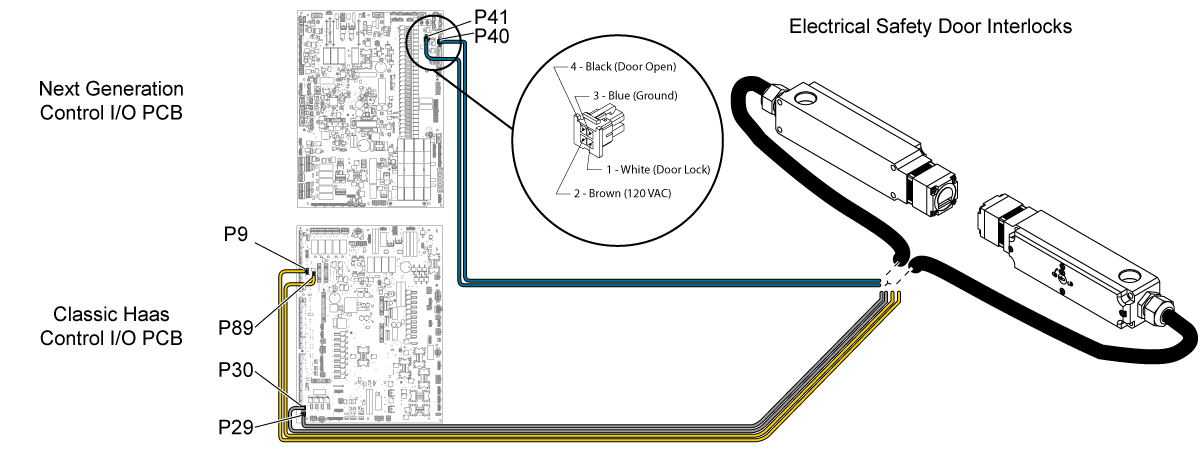

Wiring Schematics

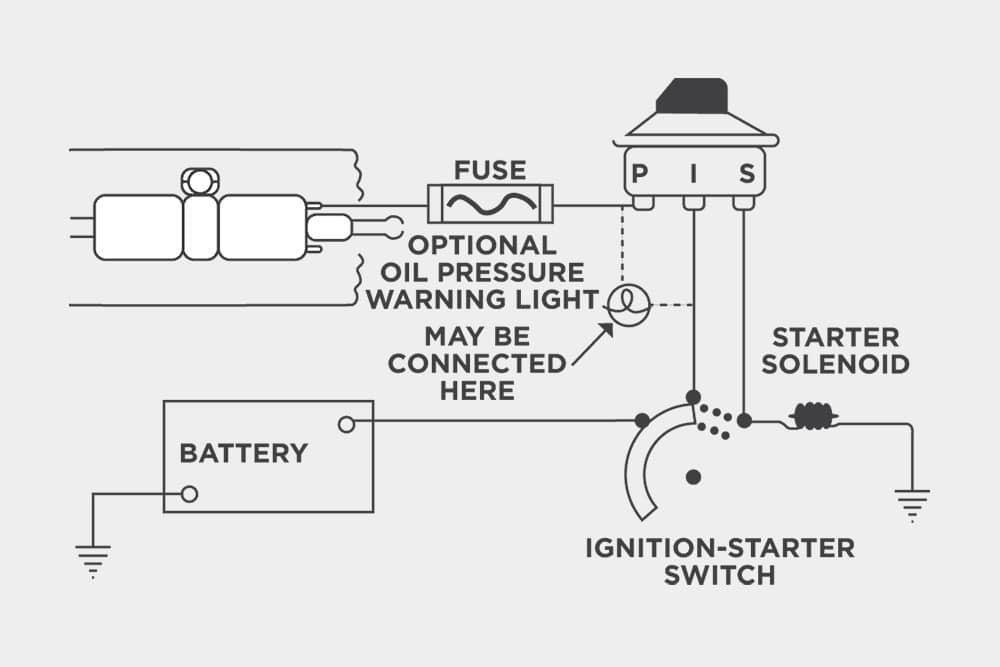

Safety interlock switch wiring diagram. Is a world leader in the design and manufacture of safety interlocks for all industries. Icc motor carrier safety regulations stipulate that the fuel pump must not continue to operate after the engine stops. Egards modular design allows configurations of purely safety gate switches purely. For non contact interlocks no physical contact under normal conditions takes place between the switch and actuator. The safety interlock circuit stops the electric fuel pump when the engine stops even though the ignition switch is not turned off the pressure switch is a single pole double throw diaphragm actuated switch. When a guard is opened hazardous machine movements eg.

Risk assessment flow diagram from iso 14121. The powered guard is a movable guard but with a safety switch that can lock the guard. A control system cannot be constructed using only. Fortress amgard range is made up of robust gate switches and solenoid interlocks designed for heavy duty applications. A tab of the clutch pedal operates it. The most prominent safety switch on many kubota tractors is located right under the seat.

The safety switches psen meet these requirements. A solution to this could be the powered guard or lockable guard. Our non contact interlock switches help you protect personnel and equipment. Remove the bolts with an 8 mm socket wrench. These functions are designed to operate correctly within the control system in which they are used. Idem safety are designers and manufacturers of safety interlock switches monitoring devices and machine sensors including many differing types of safety switch including rope safety switches rfid switches and safety relays the idem range includes safety switches non contact safety interlock switches safety relays and safety sensors.

A safety relay detects wire breaks and faulty contactorsactuators by. At the same time flexibility and productivity are points that you must also consider as you design your safety system. For example on the kubota b7800 the clutch safety switch is under the left floorboard. Certain applications also require the safety gate to be interlocked until the hazardous production process is complete. Must be stopped and a restart must be preventedit must not be possible to either defeat or manipulate the guards. Craftsman wiring and safety switches quick video for youtube user bleachedpc hopefully this will help you out.

Plug in a new parking brake safety switch and reinstall the two 8 mm bolts. Safety components the safety components that are used in these circuit examples are equipped with functions such as a direct opening mechanism for switches and a forcibly guided mechanism for relays as required by standards. Two bolts hold the switch to the frame. Craftsman riding lawn mower clutch interlock switch 532176138 duration. Unplug the switch from the wiring harness. Even though a safety switch with interlock is in use.

Locate the parking brake safety switch under the front fender on the left hand side.