813 mains supply 525600 v fc 302 only 37 814 mains supply 525690 v fc 302 only 40 82 mains supply 43 83 motor output and motor data 43 84 ambient conditions 44 85 cable specifications 44 86 control inputoutput and control data 44 87 fuses and circuit breakers 48 88 connection tightening torques 55 89 power ratings weight. Figure adjustable frequency drive block diagram.

Vlt Diagnostics Click On The Button Above Your Keypad Ppt

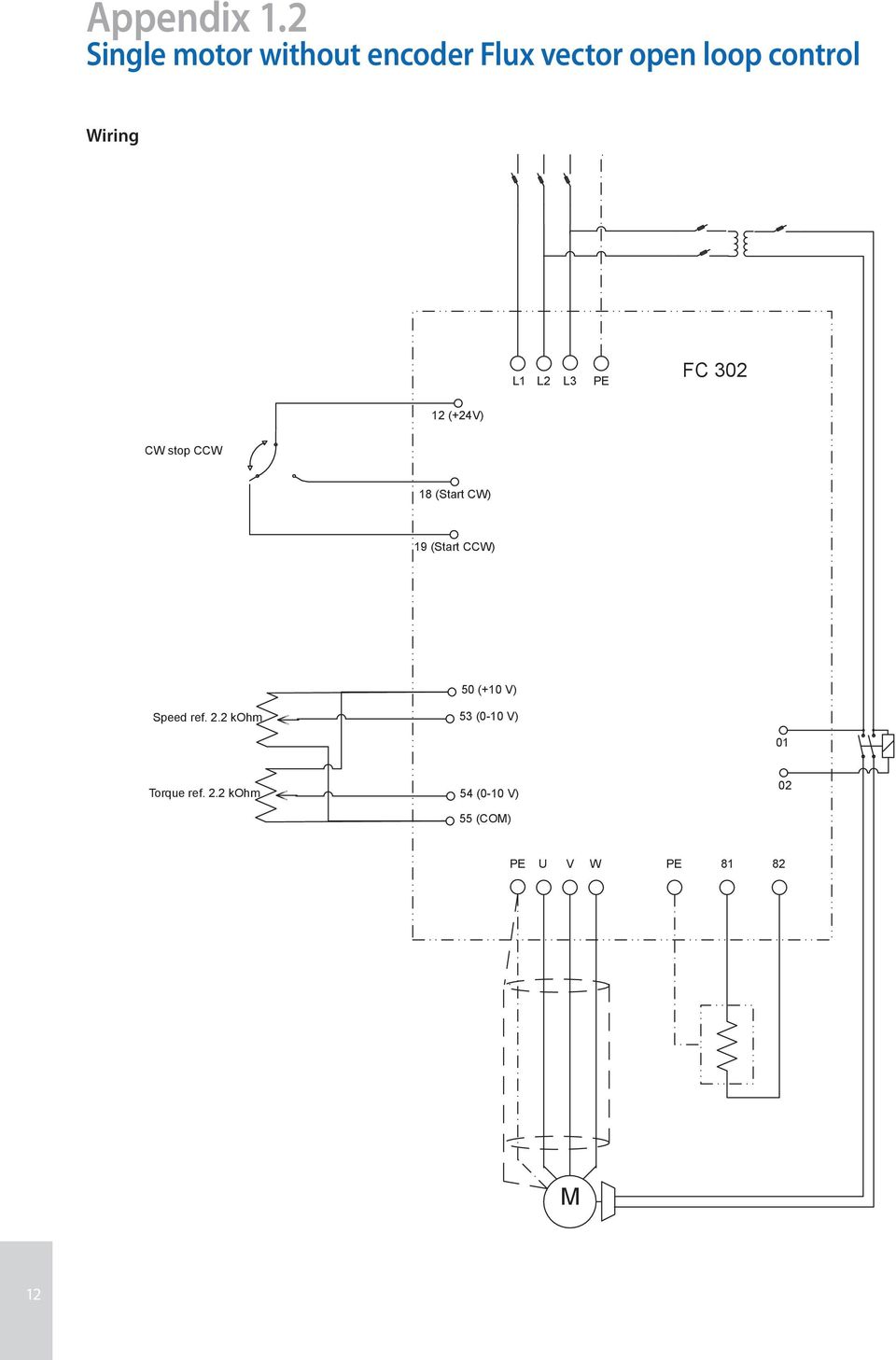

Danfoss fc 302 wiring diagram. Vlt hvac drive fc 102 fln. 134 references 5 135 miscellaneous 5 14 safety 7 15 electrical wiring 9 16 integrated motion controller 11 2 how to program 12 21 graphical and numerical local control panels. Operating guide aq. Contents 1 introduction 4 11 purpose of the manual 4 12 additional resources 4 13 document and software version 4. Vlt hvac drive fc 102 11 90 kw. The vlt automationdrive fc fc design.

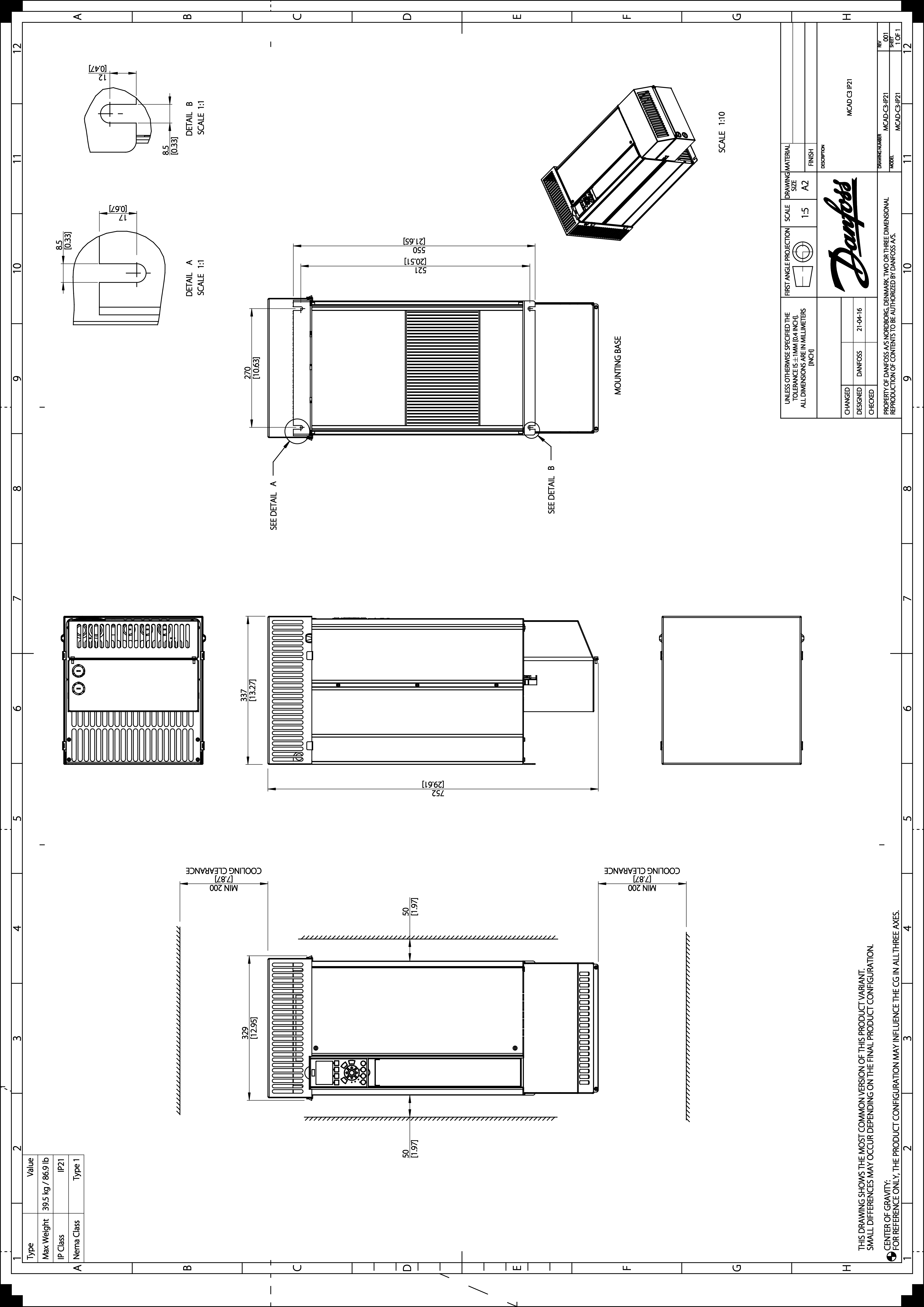

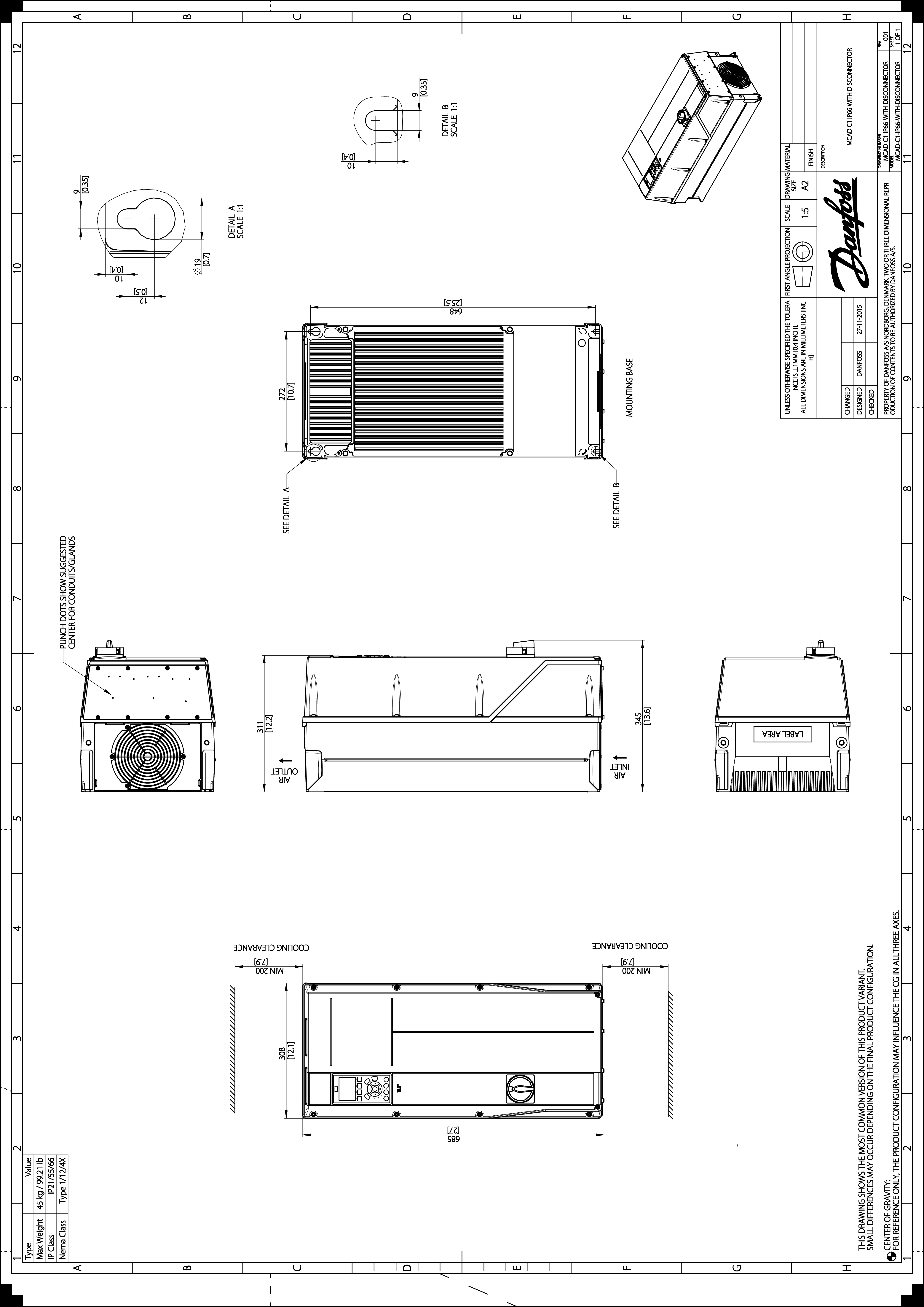

View online or download danfoss vlt automationdrive fc 302 user manual instruction manual installation manual. With the fcd 302 it is possible to reduce costs by placing the power electronics decentrally. It comes in a standard version fc 301 and an advanced high dynamic version fc 302 with additional functionalities. Central panels are then rendered obsolete saving cost space and effort for installation. 16122018 16122018 3 comments on danfoss fc302 wiring diagram. Vlt hvac drive fc 102 355 1400 kw.

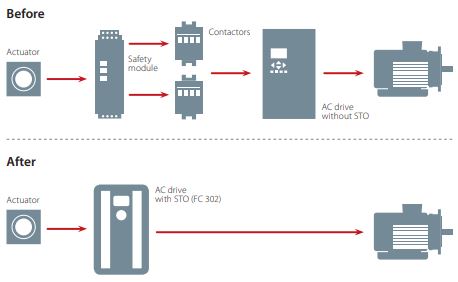

Design guide aj. Mg33am22 vlt is a registered danfoss trademark. Danfoss vlt automationdrive fc 302 pdf user manuals. Contents vlt automationdrive fc 301302 2. 44 wiring schematic 13 45 access 15 46 motor connection 15 47 ac mains connection 16 48 control wiring 16 481 control terminal types 17 482 wiring to control terminals 18 483 enabling motor operation terminal 27 18 484 voltagecurrent input selection switches 19 485 safe torque off sto 19 486 rs 485 serial communication 19. The vlt decentral drive fcd 302 is designed for decentral mounting for example in the food and beverage industry or for other material handling applications.

Fc 302 control principle 19 363 control structure in vvc 20 364 control structure in flux sensorless fc 302 only 21 365 control structure in flux with motor feedback fc 302 only 22 contents vlt automationdrive fc 301fc 302 design guide 025 75 kw. Vlt automationdrive fc 301302 software versions control card mk ii. 3420 wiring to control terminals 52 3421 electrical installation control cables 53 3422 switches s201 s202 and s801 55 35 connection examples 56. To run sto more wiring for the frequency converter is. 35 wiring schematic 16 36 controls 18 361 control principle 18 362 fc 301 vs. The vlt automationdrive is designed for variable speed control of all asynchronous motors and permanent magnet motors.