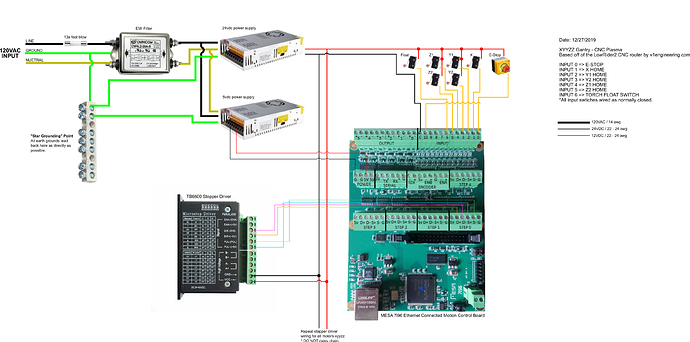

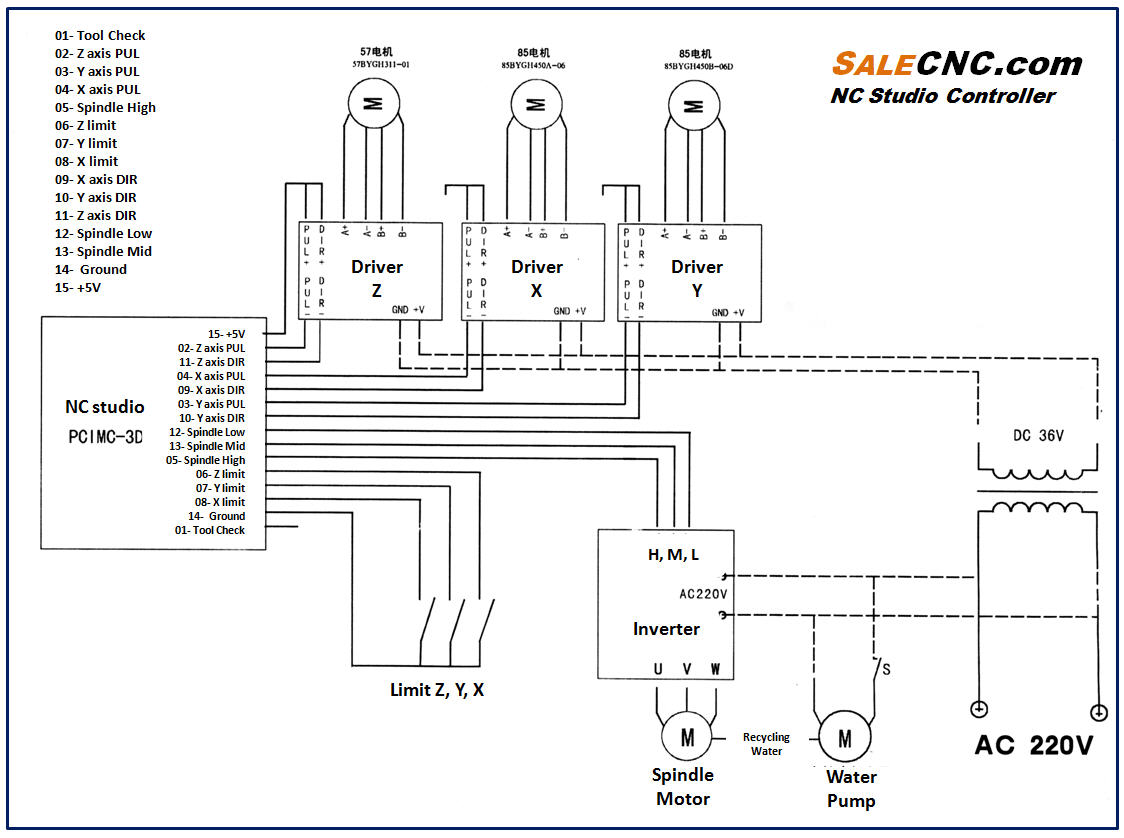

It has three axes x y and z. Wiring diagram for power supplies v posv c v com gnd l n l n l n switch mode psus 48 volt with our low inductance nema 23 stepper motors page 3.

Em 1296 In Addition Plasma Cutter Consumables On Diy Plasma

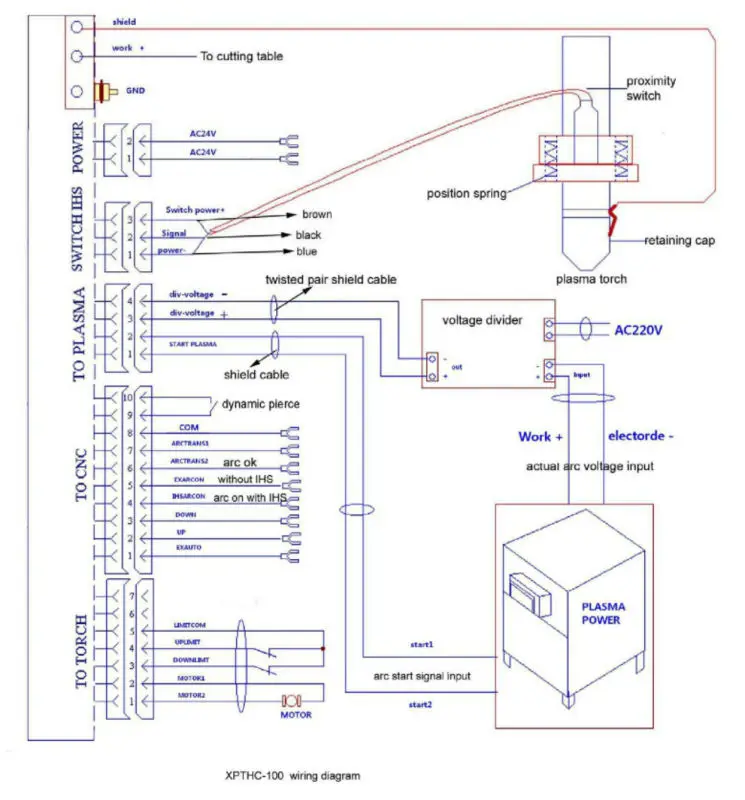

Cnc plasma wiring diagram. This machine has been refreshed with a new unitized design and touchscreen interface for all 5x10 models. Noise generated by plasma cutters etc. My wiring is specific to plasma cutting. This machine is also available in larger sizes of 6x14 6x22 8x14 and 8x22 with our standard control system. The torchmate x table is our light industrial cnc plasma cutting machine. The new parallel breakout board appears a bit different but the process of wiring and testing is the same.

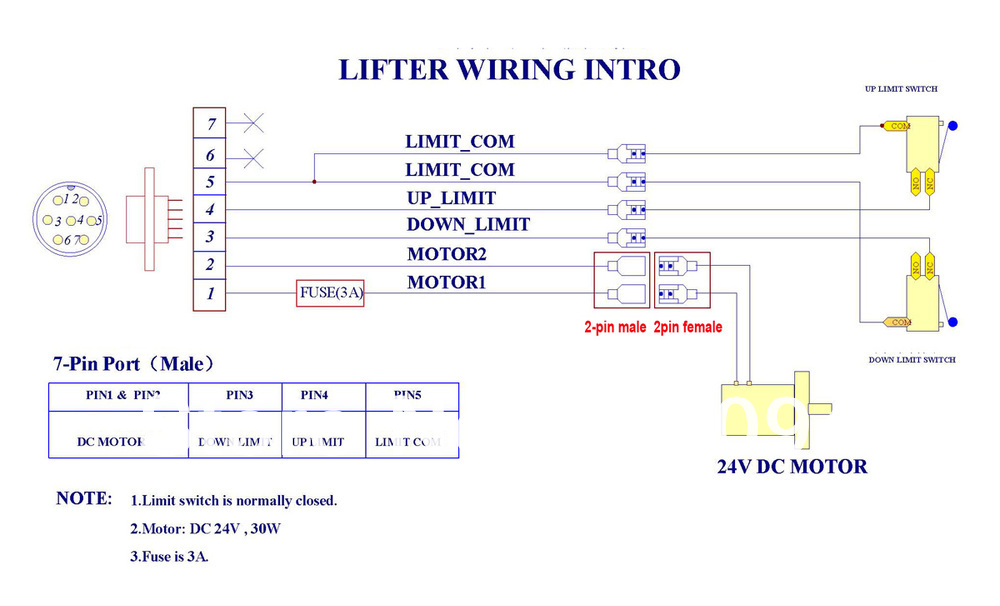

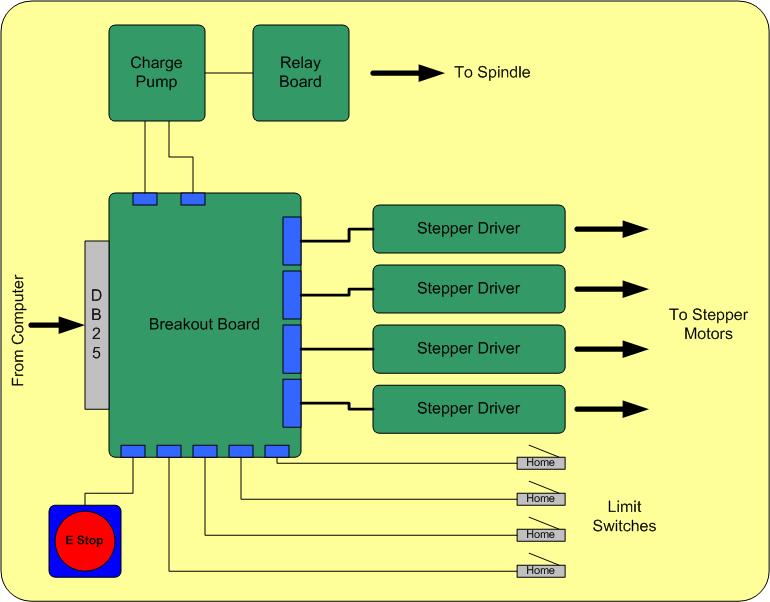

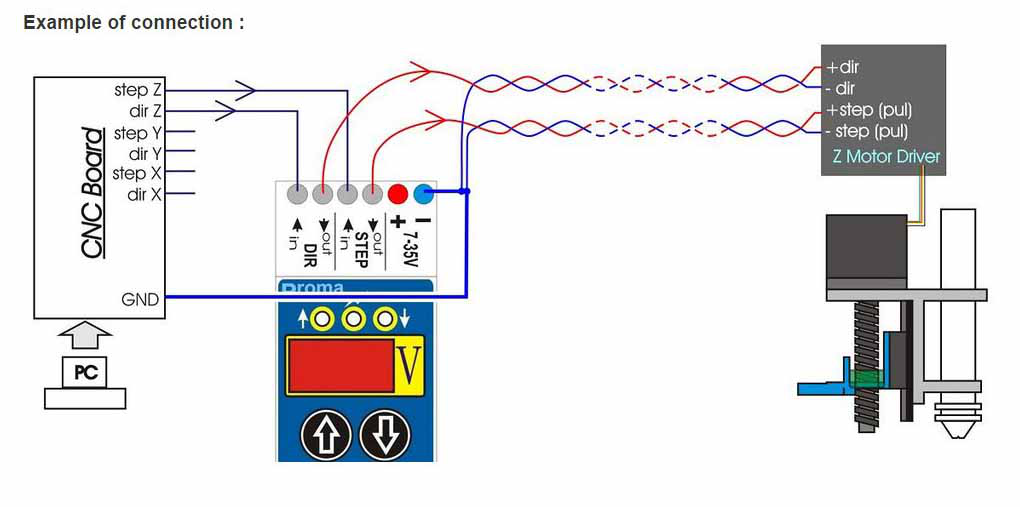

This is how ive wired it up which may differ a little from the hobbycncaustralia site linked above. A cnc plasma cutter has a similar operation with a plotter and controls by a computer. Stepper motor or servo motor will drive each axis and work together going forward backward left right and up down in perfect synchronization to produce shapes of virtually any design. Wiring diagram information is specific to our products and can cause damage if used with none compatible products so please. Above you can see a picture of the breakout board. The wiring of the parallel breakout board from the output terminals to the driver digital pulse step pulse and direction lines are explained.

Stepper motor 57hs64 3008 15nm. Will require filtering to allow stable operation of your cnc or automated machinery. However terminal blocks 123456 7 are as follows. The wiring of the stepper drivers is exactly the same. If used in industrial noisy enviroment or with plasma tables please use separate psu to power hg08 of 9 to 24volts dc and mains 240vac filtering may me required. Go to the new parallel breakout board to get more information and the wiring diagram.