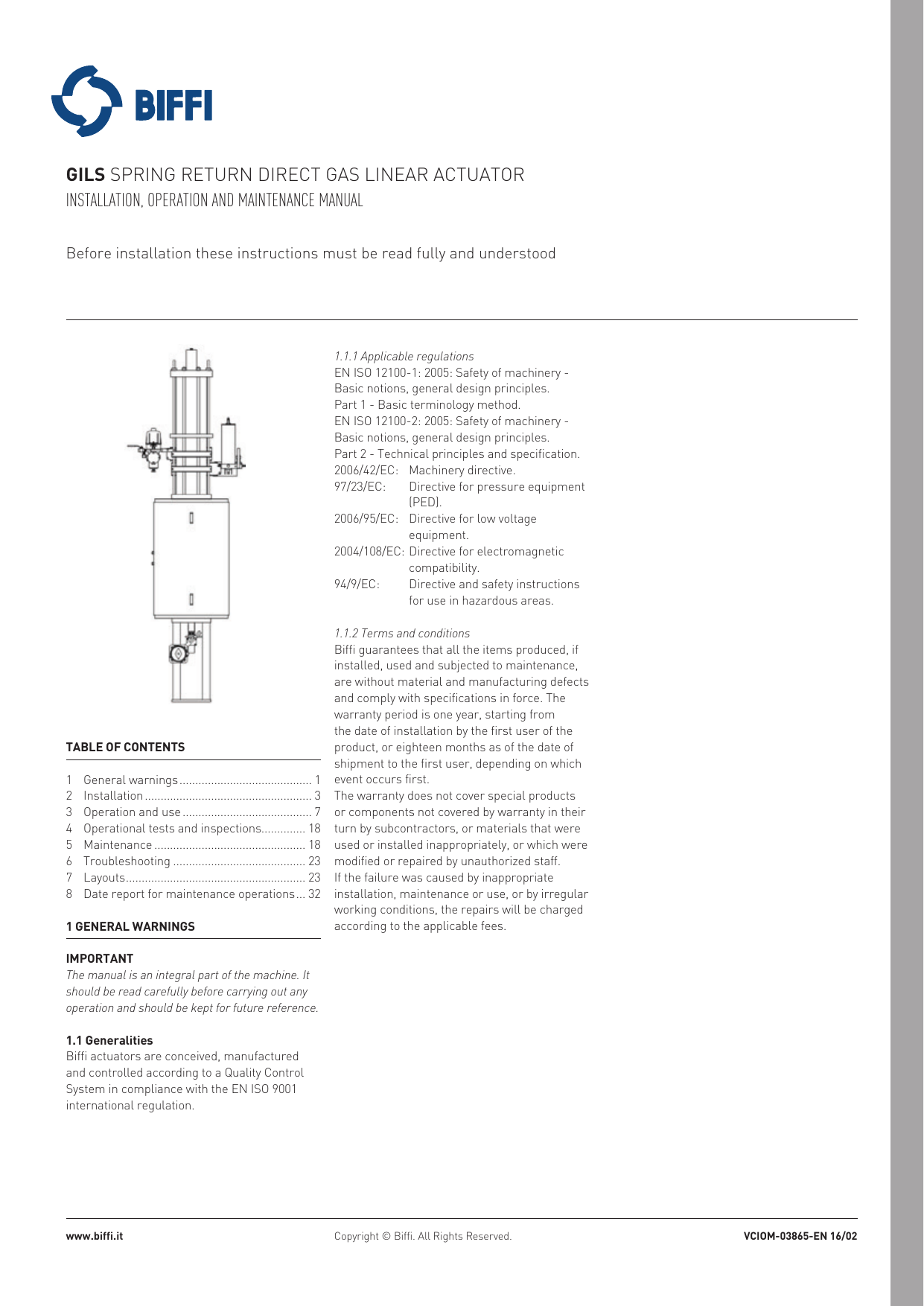

Ip6668 nema 44x6 according to nema ics6 nema 250. Operate the handwheel to drive the actuator into the desired position.

Details About Biffi Tyco F02 E13 Electric Actuator Valve Svf A890 5a 3 1 2 Free Shipping

Biffi actuator wiring diagram. Biffi f02 quarter turn electric actuator installation maintenance instructions 14 identification 141 water dust proof version f02 actuators are designed and manufactured according to en 60529 standards. Multiple actuators positioned by the same control signal may be powered from multiple transformers provided the following rules are followed. Specific types of protection are printed on the label as follows. Machine description 21 general the epi 2 is an electric quarter turn actuator. It shows the components of the circuit as simplified shapes and the faculty and signal links between the devices. Directive 9837 is biffi italia as specified on the actuator label.

Biffi is one of the worlds leading manufacturers of valve actuators. Icon 2000 electric actuators component parts 1 1 housing aluminium 2 1 lower bearing carbon steel 3 1 hollow shaft carbon steel 4 1 worm wheel bronze 5 1 circlip carbon steel 6 1 driver sleeve cast iron 7 1 driver sleeve spring carbon steel 8 1 spring retaining ring carbon steel 9 1 seal kit 91 1 o ring fpm rubber 92 1 seal ring nbr. Biffi actuator wiring diagram wiring diagram is a simplified satisfactory pictorial representation of an electrical circuit. Technical data power supply. Valves used in heavy industrial chemical and petrochemical plants. 1 wires from all actuators are tied together and tied to the negative leg of the control signal.

For models 006 through 270 the jackscrew must be returned to the fully retracted position before actuator can resume normal operation. How we use cookies. From 12 to 173 rpm at 50 60 hz ambient temperature standard range. We use cookies and similar technologies to improve our website to personalize website content to you and to deliver advertising messages and offers on content that are relevant to you. How we use cookies. Biffi icon 2000 instruction and operating manual 2 storage and pre installation 21 tests to be carried out when the actuator is received if the actuator is received already mounted on the valve all operations should have already been performed during valveactuator assembly check that the display is active.

Wire type and wire installation tips. 3 phase from 208 v to 690 v at 50 60 hz 1 phase from 110 v to 240 v at 50 60 hz dc direct current from 24 v to 110 v torque output. Figure 1b 1421 atex label for application in hazardous areas a manufacturer logo b product model. Valve position can be verified by checking the actuator position indicator. From 30 to 334000 nm speed range. With an engineering pedigree of 60 years plus and a truly global presence the company is also the partner of choice for operators seeking not just a comprehensive range of standard actuators but the finest customized solutions.

The transformers are properly sized. Back the jackscrew out until it stops.